Dust collectors designed for HEPA filtration system applications remove particles with sizes ranging from submicron to several hundred microns in diameter, with efficiencies in excess of 99.97 percent. These filtration systems are employed in industrial and institutional environments where contamination control is a must and extremely high particulate removal efficiencies are a matter of function and necessity.

HEPA filtration is principally used, most notably, to filter the airstream of contaminants in healthcare or biomedical related institutions. This would include hospitals, convalescent hospitals, residential healthcare facilities, nursing homes, medical and biomedical offices, research laboratories, health clinics, extended care facilities, or institutions devoted to healthcare. However, HEPA filtration systems also have many industrial applications. Contamination controlled environments are vital to integrated circuit fabrication manufacturing, in data centers, which are required for aerospace, automotive, agriculture, chemical, and nuclear industry applications, in food and pharmaceutical production, as well as for certain homes and offices. They can also be installed where the captured dust is hazardous or toxic to employees.

What is a HEPA Filter System?

A HEPA filter is a type of pleated mechanical filter that meets the HEPA standard of efficiency. HEPA, an acronym for High-Efficiency Particulate Absorbing filter, is a standard of efficiency for particulate filtration. A HEPA filter is designed to remove at least 99.97% of any airborne particles and particulate matter such as dust, pollen, mold, moisture, bacteria, viruses, and liquid aerosols to the size of 0.3 microns (µm). a HEPA air filter must remove these particles from the air that passes through it with at least 99.95% to the ISO, European Standard, or 99.97% by the ASME and U.S. DOE standards.

Advantages and Disadvantages of HEPA Filters

With its near 100 percent effectiveness in removing airborne contaminants to 0.3 microns or larger, HEPA filtration systems offer exceptionally high efficiency in eliminating not only inorganic airborne dust from the air but also harmful microscopic organisms. The effectiveness of HEPA filters is in the design itself. They feature a thick, pleated media rather than the typical flat fiberglass or fabric material used as media in standard filtration systems. Pleated filters expand the surface area for filtration and physically prevent airborne particles or particulates from passing through the media, keeping harmful or damaging particulate matter from entering into interior spaces. Additionally, HEPA filtration system designs are available with carbon or activated charcoal inserts to filter odors and fumes.

Nevertheless, it should be noted that HEPA filter applications are limited to filtration systems designed to meet HEPA standards. A HEPA filter cannot, or should not, be used in just any system. HEPA filters could actually damage or increase energy costs in a filtration system that the filters are not designed for, such as HVAC systems. This is related to the media itself. By design, the high-efficiency air filters consist of dense and thick material, the very properties that give the filters its unique advantage over other media in removing harmful airborne particulate matter. In HVAC systems not designed for the filters, these important properties can substantially impede the airflow through HVAC equipment. Consequently, if the airflow is restricted through the system, it will take longer to heat or cool a space or property. A longer running system can lead to premature wear of equipment parts and components, as well as increased utility costs.

HEPA Industrial Air Filtration Systems

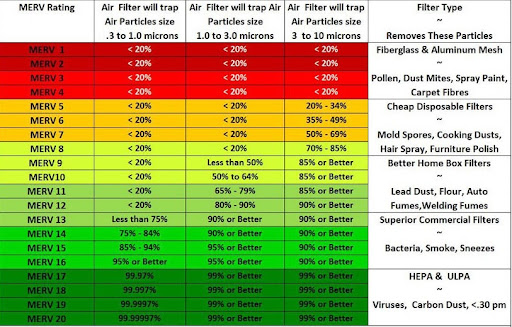

HEPA air filtration systems are specifically designed to meet HEPA standards or filtration at or above MERV 17.

Filtration for various MERV ratings

Particularly so for industrial dust collection applications, the HEPA filtration system must provide maximum air cleaning efficiency combined with extremely high particulate removal required for the given workplace and/or production environment. These systems may be either stand-alone units for use in smaller spaces or can be integrated with standard pulse-jet style dust collector systems. If HEPA level filtration is not required, MERV 11 to MERV 16 filters may be a reasonable cost alternative to provide secondary filtration in the event the filtered air is to be returned back to the workspace.

CPE Filters offers its customers either stand-alone or integrated pulse-jet HEPA filter systems. For large-scale dust collection needs, pulse-jet collection units can incorporate CPEF™ filter bags or spun bonded polyester cartridges that provide collection efficiencies up to 99.9% for most typical industrial applications. The unique design provides greater efficiency as well as cost savings, followed by a CPEF customized HEPA filtration system.

For more information on HEPA industrial filtration systems or to discuss your company’s HEPA filtration requirements, contact CPE Filters today.